Push Back Systems

Carts nest on top of each other and are pushed back as pallets are loaded.

Concentric Push Back Systems are designed for last-in-first-out (LIFO) applications. These type of systems yield a faster inventory turnaround and reduce aisle spacing. The Push Back Systems can hold a high number of pallets while maintaining a low number of SKUs. Nested carts fueled by gravity flow carry carts to picking position.

LIFO – “Last-In-First-Out” Inventory Especially beneficial if flowing date sensitive or perishable products is not critical.

Pallet Depths

Depending on the forklift capabilities versus the pallet load weight, Push Back Flow Systems can be up to 6 pallets deep. Low-profile carts help conserve vertical space within the bay.

Organized Inventory

Contributes to faster, more efficient order fulfillment.

Inventory Audits

Performed in less time with increased accuracy.

Less Pilferage & Product Damage

When pick faces are reduced, pilferage is decreased (less access to the product). Also, minimum product handling ensures less product damage.

Increased Safety

Fewer aisles provide a safer environment for pedestrian traffic throughout the warehouse.

Reduced Overhead Expenses

Reduced warehouse space equals energy savings. Reduced number of forklifts equals lower equipment maintenance cost and also less space required for maintenance.

As a pallet is loaded from the aisle, it pushes the pallet behind it back one position. When the front pallet is removed, the rear pallets automatically come forward to the front picking position.

Gravity does the work.

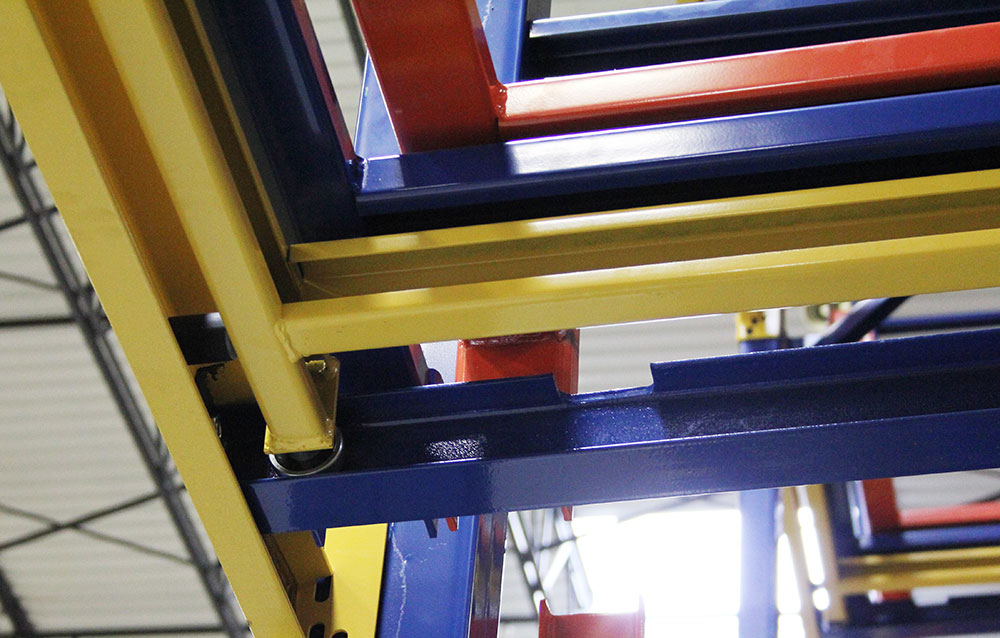

Push Back Rails Secure Carts

Notched Push Back Rails help protect carts from uplift within the bay as pallets flow forward. Carts stay linked which helps eliminate product damage or cart derailment. Rail supports are located at center beams within the pallet rack bays to help keep the push back system aligned. The number of rail supports is dependent on the depth of the system and weight loads of pallets used.